Plastic Recycling Extruders

Unlocking the Potential of Plastic Recycling Extruders: A Sustainable Solution for Plastic Waste Management

In the era of environmental consciousness, the global community faces an increasingly urgent challenge: plastic waste. Plastic pollution has permeated every corner of the planet, from the depths of the oceans to the peaks of the highest mountains. Despite heightened awareness and efforts to curb plastic consumption, the volume of plastic waste continues to rise. In this battle against plastic pollution, recycling emerges as a vital weapon, and at the forefront of this battle are plastic recycling extruders.

Understanding Plastic Recycling Extruders

Plastic recycling extruders are innovative machines designed to tackle the daunting task of recycling plastic waste. At their core, these extruders function by melting down plastic waste and reforming it into usable products. The process involves several stages:

Collection and Sorting: Plastic waste is collected from various sources, including households, industries, and municipalities. It undergoes sorting to separate different types of plastics, such as PET, HDPE, PVC, and others, as each type requires specific recycling processes.

Shredding: The sorted plastic waste is then shredded into smaller pieces to increase its surface area and facilitate melting. This step is crucial for achieving uniform melting and ensuring the quality of the recycled material.

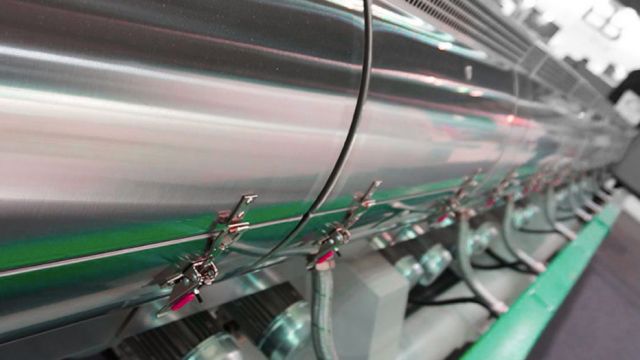

Extrusion: The shredded plastic is fed into the extruder, where it undergoes melting at high temperatures. The molten plastic is then forced through a die to give it a specific shape or form. This process can be tailored to produce various products, including pellets, sheets, filaments, and even 3D printing filament.

Cooling and Solidification: Once extruded, the newly formed plastic undergoes cooling to solidify into its final shape. This step is essential for maintaining the integrity and strength of the recycled material.

Finishing and Quality Control: After solidification, the recycled plastic may undergo additional processing, such as cutting, shaping, or surface treatment, to meet specific requirements. Quality control measures ensure that the recycled material meets industry standards and regulatory guidelines.

Advantages of Plastic Recycling Extruders

Plastic recycling extruders offer a multitude of benefits, making them a preferred choice for tackling plastic waste:

Resource Conservation: By recycling plastic waste, extruders help conserve valuable resources that would otherwise be consumed in the production of virgin plastic. This includes reducing the demand for crude oil, which is a primary raw material for plastic production.

Energy Efficiency: Recycling plastic typically requires less energy compared to manufacturing virgin plastic. Extruders optimize energy consumption by utilizing efficient heating and cooling processes, further reducing the environmental footprint of plastic recycling.

Waste Reduction: By diverting plastic waste from landfills and incinerators, recycling extruders contribute to the reduction of environmental pollution and greenhouse gas emissions associated with waste disposal.

Versatility: Plastic recycling extruders are versatile machines capable of processing a wide range of plastic materials, including both post-consumer and post-industrial waste. This flexibility allows for the recycling of diverse plastic products, from packaging materials to automotive components.

Circular Economy: Recycling extruders play a crucial role in advancing the concept of a circular economy, where resources are continuously reused and recycled, minimizing waste and maximizing resource efficiency.

Job Creation: The growing demand for plastic recycling solutions creates opportunities for job creation in the recycling industry. From machine operators to recycling technicians, the deployment of recycling extruders stimulates employment growth while addressing environmental challenges.

Challenges and Innovations

Despite their numerous advantages, plastic recycling extruders face several challenges that hinder their widespread adoption and effectiveness:

Contamination: Contamination of plastic waste with non-recyclable materials poses a significant challenge for recycling extruders. This contamination can degrade the quality of the recycled material and compromise the performance of the extrusion process. Innovations in sorting technologies and consumer education efforts are essential for minimizing contamination and improving recycling efficiency.

Technical Limitations: Some types of plastic, such as mixed plastics or composites, are difficult to recycle using conventional extrusion methods. Research and development efforts are underway to develop advanced extrusion technologies capable of processing challenging plastic materials and expanding the range of recyclable plastics.

Economic Viability: The economics of plastic recycling can vary depending on factors such as market demand, material prices, and recycling infrastructure. While recycling extruders offer long-term environmental benefits, the initial investment and operating costs may present challenges for recycling facilities, particularly in regions with limited financial resources. Policy interventions, such as extended producer responsibility schemes and recycling incentives, can help address these economic barriers and promote the adoption of recycling extruders.

Regulatory Compliance: Compliance with regulatory standards and environmental regulations is critical for the operation of recycling extruders. Ensuring compliance requires ongoing monitoring of emissions, waste disposal practices, and product quality to mitigate environmental risks and safeguard public health.

In response to these challenges, researchers and manufacturers are continuously innovating to enhance the performance, efficiency, and versatility of plastic recycling extruders. Emerging technologies, such as advanced sorting systems, robotic automation, and additive manufacturing, promise to revolutionize the plastic recycling industry and accelerate the transition to a circular economy.

The Road Ahead

Plastic recycling extruders represent a beacon of hope in the fight against plastic pollution, offering a sustainable solution for managing the growing tide of plastic waste. However, realizing their full potential requires collective action and collaboration among stakeholders across the plastic value chain, including producers, consumers, policymakers, and recycling industry players.

Key strategies for unlocking the potential of plastic recycling extruders include:

Investment in Infrastructure: Governments and private sector entities should invest in the development of recycling infrastructure, including collection systems, recycling facilities, and recycling extrusion technology. This investment is essential for building a robust recycling ecosystem capable of handling the volume and diversity of plastic waste.

Education and Awareness: Public education campaigns play a crucial role in promoting responsible consumption habits and increasing awareness of plastic recycling opportunities. By educating consumers about the importance of recycling and proper waste management practices, we can reduce contamination and improve the quality of recycled materials.

Policy Support: Governments can enact policies and regulations that incentivize recycling and promote the use of recycled materials in manufacturing processes. This includes measures such as extended producer responsibility, landfill taxes, and procurement policies favoring recycled products.

Collaborative Innovation: Collaboration between industry stakeholders, research institutions, and technology providers is essential for driving innovation and overcoming technical challenges in plastic recycling. By sharing knowledge, resources, and best practices, we can accelerate the development and adoption of cutting-edge recycling technologies.

Plastic recycling extruders represent a critical piece of the puzzle in our quest for a more sustainable future. By harnessing the power of innovation, collaboration, and collective action, we can unleash the full potential of these transformative machines and pave the way towards a world where plastic waste is no longer a burden but a valuable resource.